How to future-proof your mine

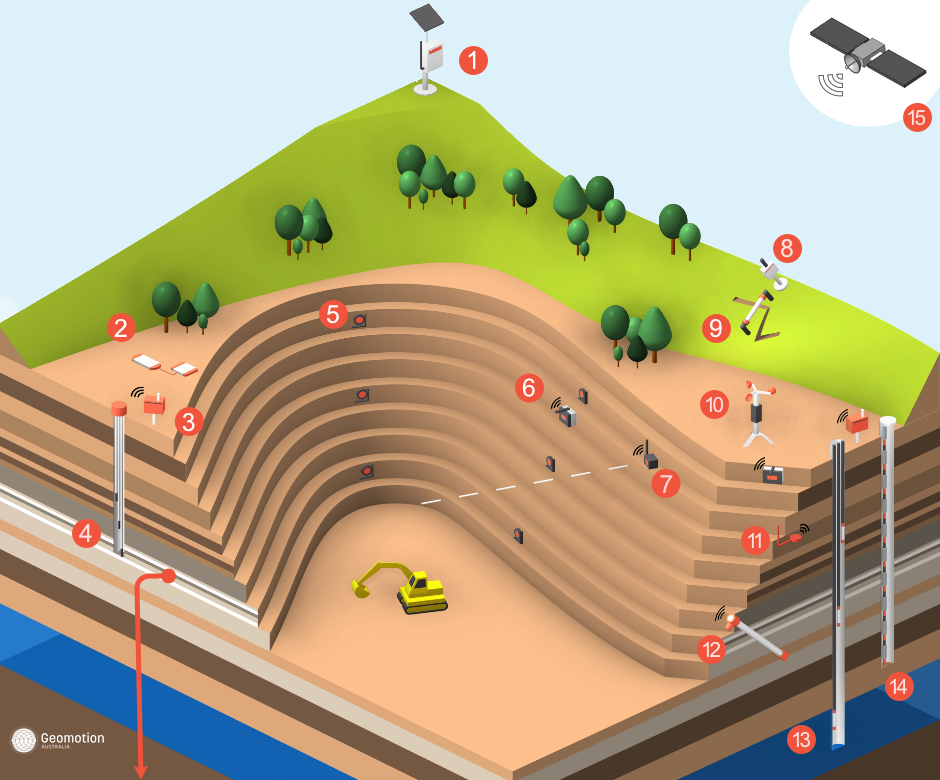

Mining operations are expanding and becoming more complex, bringing with it multiple geotechnical challenges. Click on the interactive infographic below to find out more about the automated system and geotechnical instruments that can be used for mine monitoring.

Mine Monitoring System

Many decisions are made on a daily basis and high-quality data should be feeding these decisions. Geomotion specialises in the assembly, supply and installation of comprehensive mine monitoring systems that can be used in and around mines to provide crucial information to stakeholders.

Data can be analysed over time, providing quality insights into the behaviour of the structure and the ground below it. If sensor readings breach a critical threshold, key stakeholders can be alerted automatically, and action plans enacted to protect the public, environment and workers.

Historical data from a mine monitoring system can be used to predict issues like slope failures signalled as excessive settlement by inclinometers and settlement plates, allowing for preventative maintenance to be completed.

Data from the system can also be used after the fact to evaluate the effectiveness of maintenance whether it is preventative or routine.

Benefits

- Reduce costs over the lifetime of the mine

- Enhance the safety of workers

- Provides insight into structural and geotechnical behaviour

- Automatic alarms and alerts for exceeding threshold values

- Comprehensive monitoring for critical areas

How it works

The data obtained through mine monitoring can be invaluable for engineers to determine if the mine is performing as planned. In the same vein, that data can be used to indicate when the geotechnical performance is poor, and when the operations should be changed to prevent failures.

Several aspects of mining operations can be monitored, from the mines themselves to tailings dams and surrounding areas. A bespoke monitoring system can be designed using more sensors in critical areas, resulting in a higher data density and more reliability. Contact our team to discuss about your mine monitoring project.

Mine Monitoring Projects

We are experienced in the monitoring of mine sites and excavations, and our geotechnical monitoring team have worked on numerous major projects including Tailings Storage Facilities (TSF) and underground and open cut monitoring. Based on state-of-the-art technology, our products are built to an accredited quality control system and designed to withstand the challenges of the most extreme environments.

Koolan Island Seawall Remediation

Geomotion was contracted for the supply, installation, maintenance and support of the geotechnical instrumentation…

Hope Downs 4, Western Australia

Geomotion have been commissioned to supply and install geotechnical instrumentation for the Waste Fines Storage Facility Project…

Premier Coal Mine, Western Australia

Premier Coal is situated in the Collie Coal Basin in the South West of Western Australia, approximately 200km south-south-east of Perth. The…

Boddington Tailings Dam Trial Embankment

Boddington Gold Mine (BGM) is located 120km south-east of Perth in Western Australia. The largest gold mine in the…

Cape Preston, Western Australia

Citic Pacific Mining enlisted MCC to construct the main causeway linking the port with the main mine hub. The 70m wide causeway carries the services…

Newman Hub, Western Australia

As part of the Rapid Growth Project 4 (RGP4), a dual trail load out structure and stockpile were constructed in the Newman Hub, by the Mount Whaleback ore…

Utah Point, Western Australia

The Port Hedland Port Authority commissioned Ertech to construct a multi-user iron ore stock yard as part of the Utah Point Berth upgrade. In order…

Boddington Gold Mine RDA, WA

Newmont’s Boddington mine is located within the Saddleback greenstone belt in Western Australia. A large gold and copper mine, Boddington…